Custom Screen Printing Seattle

The Foundry Print Shop is Seattle’s original premium supplier of customer screen printing. With our vast service selection and stellar customer service you’ll find us the be the one stop shop for all your custom apparel needs. If it’s printed tee shirts or custom screen printed sweatshirts we’ve got you covered. See us for screen printed accessories also such as custom hats, totes and backpacks.

If you’re looking for the highest quality in screen printing and silkscreen in Seattle than look no further!

Screen printing is at the center of all project here at The Foundry. Almost all jobs that come across our production board contain printed garments in some form. Also known as silk screening, screen printing is by far the most diversely applied method for garment decoration.

Ways you can use screen printing

You can use screen printing in so many application scenarios it’s hard to remember them all but let’s talk about the most popular forms. First is obviously your standard front, back or sleeve print applied directly onto the garment.

Screen printing is also used to apply care and size information to the inside collar of the garment. This is a great way to add perceived value and brand recognition to your printed tee shirt and printed hoody projects.

Another very prevalent system that utilizes screen printing is plastisol transfers or screen-printed transfers. These transfers are great for applying screen printed images to items that are irregularly shaped or heat sensitive. Items like printed outerwear, printed hats and accessories are all common items embellished with plastisol transfers.

Types of screen-printing inks

There are also several ink systems used in screen printing with plastisol being the most common. Plastisol screen printing applies a thin polymer film to the surface of the fabric. Traditionally people think of plastisol as a thicker print, but that’s not really the case with modern plastisol inks.

Other popular ink systems for screen printing are water base and water-based discharge inks that essentially dyes the material. Water based printing is a great system but is only compatible with 100% cotton or very polyester light blends. Lastly we offer acrylic screen printing, similar to plastisol inks but lighter weight and more eco friendly.

There’s a ink system for every print project.

As I mentioned above, screen printing is a very diverse process and we’re always finding new ways to use it. Come to us with your project and you can be assured that we’ll find the best practices to produce optimum results.

We know that the screen printing process can be hard to understand so we wanted to take a second and go over the key factors involved.

All screen printing projects start at the art and garment, we need to discern what process would be ideal to render the screen printing stencils and to what material the screen print will be applied.

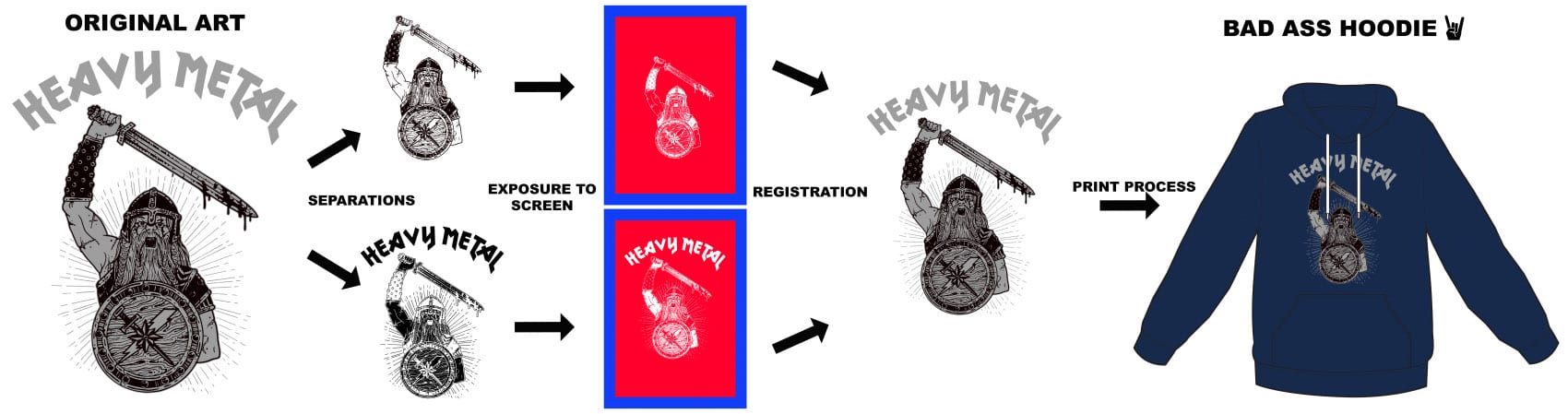

First we create what we call separations, this is the process of dividing your art into the positives also known as films that will represent the screen print stencils. There are several different ways to do this depending on the complexity of the art. For most prints we will just separate them into spot colors. For complex separations we use what’s called simulated process, simulated process involves screen printing a series of halftone dots to create a larger overall image. The tiny halftone dots allow you to create extremely fine details in your screen prints. Where different colors of dots overlap, your individual ink colors begin to blend together.

Next we use those positives to expose the information from each color into individual screens creating the stencil, the screen print stencil is then the positive information that the ink will pass through to the garment.

Now that the screens contain the stencils we align all the screens on the printing press so the art fits back together like a puzzle, this is called registration. Registration is a very crucial part of quality screen printing and is possibly the most difficult part of the screen printing process to master.

Once we have everything on press we can start test printing the project. Setting up the squeegee pressure, pre-cure temperatures, print speeds and final touches to registration. We have learned through the years that’s it’s always better to run a few more test before you start your production screen printing.

Creating quality screen printing is all done in the setup stage, when mindful steps are taken by experienced printers the production stage is smooth sailing.

Check out the infographic below showing the basics on separations, exposure and registration.

Custom Screen Printing Seattle

Here at The Foundry Print and Embroidery shop we offer all types of screen printing in Seattle to accommodate your custom apparel projects. Screen printed tees, hoodies, sweatshirts and more!

Screen printing is at the center of all project here at The Foundry. Almost all jobs that come across our production board contain printed garments in some form. Also known as silk screening, screen printing is by far the most diversely applied method for garment decoration.

Ways you can use screen printing

You can use screen printing in so many application scenarios it’s hard to remember them all but let’s talk about the most popular forms. First is obviously your standard front, back or sleeve print applied directly onto the garment.

Screen printing is also used to apply care and size information to the inside collar of the garment. This is a great way to add perceived value and brand recognition to your printed tee shirt and printed hoody projects.

Another very prevalent system that utilizes screen printing is plastisol transfers or screen-printed transfers. These transfers are great for applying screen printed images to items that are irregularly shaped or heat sensitive. Items like printed outerwear, printed hats and accessories are all common items embellished with plastisol transfers.

Custom Screen Printing Seattle

Here at The Foundry Print and Embroidery shop of Seattle we offer all types of screen printing to accommodate your custom apparel projects. Screen printed tees, hoodies, sweatshirts and more!

Screen printing is at the center of all project here at The Foundry. Almost all jobs that come across our production board contain printed garments in some form. Also known as silk screening, screen printing is by far the most diversely applied method for garment decoration.

Contact us with your custom screen printing project today!

Types of screen-printing inks

There are also several ink systems used in screen printing with plastisol being the most common. Plastisol screen printing applies a thin polymer film to the surface of the fabric. Traditionally people think of plastisol as a thicker print, but that’s not really the case with modern plastisol inks.

Other popular ink systems for screen printing are water base and water-based discharge inks that essentially dyes the material. Water based printing is a great system but is only compatible with 100% cotton or very polyester light blends. Lastly we offer acrylic screen printing, similar to plastisol inks but lighter weight and more eco friendly.

There’s a ink system for every print project.

As I mentioned above, screen printing is a very diverse process and we’re always finding new ways to use it. Come to us with your project and you can be assured that we’ll find the best practices to produce optimum results.

We know that the screen printing process can be hard to understand so we wanted to take a second and go over the key factors involved.

All screen printing projects start at the art and garment, we need to discern what process would be ideal to render the screen printing stencils and to what material the screen print will be applied.

First we create what we call separations, this is the process of dividing your art into the positives also known as films that will represent the screen print stencils. There are several different ways to do this depending on the complexity of the art. For most prints we will just separate them into spot colors. For complex separations we use what’s called simulated process, simulated process involves screen printing a series of halftone dots to create a larger overall image. The tiny halftone dots allow you to create extremely fine details in your screen prints. Where different colors of dots overlap, your individual ink colors begin to blend together.

Next we use those positives to expose the information from each color into individual screens creating the stencil, the screen print stencil is then the positive information that the ink will pass through to the garment.

Now that the screens contain the stencils we align all the screens on the printing press so the art fits back together like a puzzle, this is called registration. Registration is a very crucial part of quality screen printing and is possibly the most difficult part of the screen printing process to master.

Once we have everything on press we can start test printing the project. Setting up the squeegee pressure, pre-cure temperatures, print speeds and final touches to registration. We have learned through the years that’s it’s always better to run a few more test before you start your production screen printing.

Creating quality screen printing is all done in the setup stage, when mindful steps are taken by experienced printers the production stage is smooth sailing.

Check out the infographic below showing the basics on separations, exposure and registration.

Why work with The Foundry over other shops?

5 things that make The Foundry your top choice.

- Ability: Our 4,000 sqft shop is full of top of the line equipment and experienced operators. With garment printing, embroidery, patches, sewing and printed vinyl all in one place we are the one business relationship for all your private label needs.

- Creativity: Our staff is passionate about apparel, art and trends both current and classic. This passion drives a know-how in our design and application approach to creating custom apparel. We help take your ideas and put them into a format that is both compatible with and unique to your intentions.

- Resourcefulness: We always promote the scenario where quality and affordability meet. There are multiple ways to execute any custom apparel project and you can count on us to plan around the best results for a practical value while maintaining our quality first credo. The Foundry’s extensive in-house resources makes for as little 3rd party vendor involvement as possible.

- Accountability: We hold ourselves accountable to the quality of product and customer experience. We encourage our customers to share their thoughts to help us meet our commitments and deliver elevated results. Understanding the customers expectations, meeting them and managing concerns is what makes us Seattle’s one stop shop for quality custom apparel.

- Convenience: It is our job to know the process and be able to convey that information to the customer for their assurance. Our invoicing system outlines all of the garment and print information. We provide detailed mockups for every project with live approval and payment links. As well as due date and shipment tracking all from a single invoice view. This makes staying in know about your project easy and streamlined. We can ship to anywhere in the country or you can pick up from our location in South Seattle.

If you are looking to create the best custom garments and a value rich relationship look no further than The Foundry Print Shop Seattle.

Our Service Area Includes: Seattle | Olympia | Spokane | Bellevue | Everett | Bellingham | Tacoma | Vancouver | Whitefish | Portland | Tri-Cities

Automated Screen Printing Presses

Screen Printing on Poly Garments

Gradient Printing

Simulated Process

Screen Printing on Nylon

Learn about some of the more common screen printing systems and methods.

Much like a dye process water-based and water-based discharge are water born systems where the print ink is absorbed into the fabric. This creates a softer, longer lasting and more environmentally friendly screen printing process. Although there are some poly blended fabrics that are compatible with water-based printing it’s recommended that only 100% cotton garments be used with this process. In some situations brighter fabric colors such as purple, royal and kelly green are not compatible with light on dark printing because they do not fully discharge.

A PVC or acrylic and liquid plasticizer ink system plastisol creates a durable surface film on the fabric. Although not as soft as water-based printing plastisol is far more versatile and when used intelligently can create a variety of desired effects. 4 color process, simulated process and metallic are all based on the plastisol ink system. We take care to minimize our footprint on the environment by using phthalates and PVC free inks when possible.

A plastisol additive that allows inks to adhere to waterproof nylon materials such as jackets and bags. Keep in mind that the temperatures needed to cure plastisol can often exceed the heat exposure recommended for treated synthetic materials, this results in having to flash cure some prints that use nylabond.

With semi-transparent plastisol inks four color process uses halftones of CMYK to create a photo-realistic print process. As a subtractive color system CMYK must be printed over a white substrate. Although white garments are ideal colored garments are compatible with this system when a white baseplate is printed under the graphic silhouette. Substrate (printing), the base material that images will be printed onto.

Much like 4 color process simulated process uses halftones to represent varied shades of a print color. However unlike 4 color process it uses solid opaque inks making it more compatible with darker garment colors.

Available in an array of colors metallics are plastisol based inks with reflective particles that create a chrome or gold like finish. Because these inks generally have a high viscosity a low mesh screen is required to print them making for a thicker ink deposit.

A plastisol ink that uses phosphorus to store surrounding light and then illuminates it in the dark. This ink is generally transparent and can be overprinted on other print colors. It glows a light green.

Fabrics that contain high amounts of synthetic fibers releases their dye when heated causing dye migration between the garment and the screen printing ink. Specially formulated poly inks are required to preserve the intended print color.

We believe that know how is what sets The Foundry Print Shop apart. Evolving with current technology while maintaining a handmade feel, finding solutions to difficult and new situations. Stoked customers and creative products with purpose.

Different fabrics require different print processes.

Cotton is ideal for screen printing because it deforms less than synthetic fibers such as polyester, nylon and acrylic when exposed to the heat needed to cure screen printing inks. It is also the only fabric type that is fully compatible with water-based discharge printing.

Blend fabrics consist of cotton and other synthetic fibers such as polyester, acrylic or nylon. It is recommended that only plastisol screen printing systems be used on poly blend fabrics because the synthetic fibers use colorfast dyes that will not discharge. Some blends are more discharge compatible than others but testing should always be done before production.

Plastisol is the only screen printing ink system compatible with nylon and other waterproof fabrics. Nylabond additive is used to bond the plastisol to the nylon for a more durable and washable print. Because the melting temperature of nylon is close to the the curing point of plastisol ink some nylon prints must be manually flash cured, however our natural gas textile dryer is effective in most situations.

Garments that have 100% synthetic content are often referred to as performance fabrics because of their ability to wick moisture and dry quickly. Due to their hydrophobic nature only plastisol inks should be used to screen print these fabrics. The high amount of synthetic fibers and colorfast dyes require specially formulated inks to prevent dye migration from the garment to the screen printing ink.

With so many fabrics on the market we customize every job to the garment being printed. If customers choose to provide their own garments we strongly suggest they consult with our staff before purchasing them.