Alright let’s take a look at Simulated Process and CMYK screen-printing methods. To fully understand what they are and why they are so commonly used you must first understand that screen-printing has two major limitations when it comes to full color renderings.

First let’s just say that screen-printing is limited to 7-8 colors, our largest press is a 10 color but rarely do we set up projects that contain more than 6 colors, anything more typically isn’t cost effective for the customer. Secondly screen-printing is a spot color process, you can only print 100% of a color, any graduation is done with halftones that simulate opacity.

If you don’t fully understand those last two sentences no worries, I’ve prepared some visuals to assist us as we go. Also check out this article for a basic understanding of the screen-printing process.

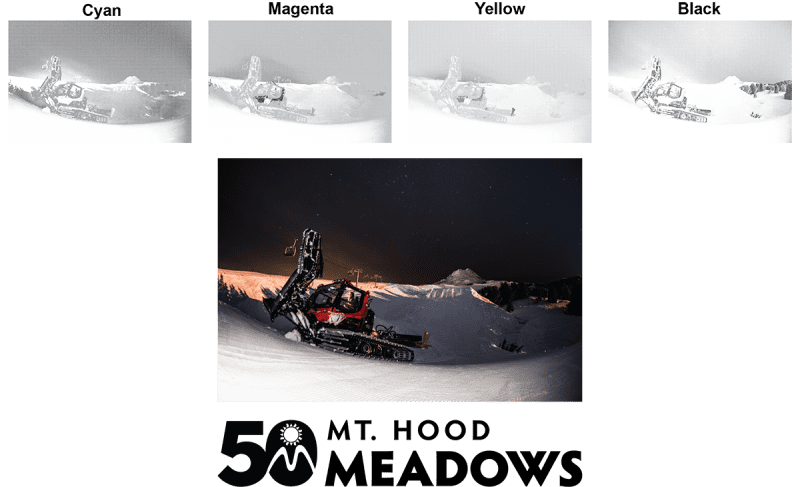

Alright let’s start with CMYK printing. CMYK is a deductive color system meaning that it subtracts colors from white (white being all the colors in the visible spectrum) the same way your desktop printer uses Cyan, Magenta, Yellow and Black (or Key color). That also means that it only works on white, very light grey or natural colored sub-straights. It sounds crazy but it’s really simple. It’s just seperating the CMYK channels and half-toning them. We print CMYK with specially formulated semi transparent inks that combine to simulate about a million colors.

Advantages of CMYK is that it can be done in 4 screens, disadvantage is that like I mentioned above it only works on light colored garments. Another note on this is that it works best on high-density finer knits.

Next we have Simulated Process printing. Unlike CMYK the Simulated Process system uses fully opaque inks making it applicable on dark colored sub-straights. Separating the art is a little more difficult than the methods used on CMYK but the principles are the same. You create channels from the art file and use halftones to simulate values of any one print color. Most art can be achieved in about 6 colors.

The advantages with Simulated Process is that it works on any color garment and is far less finicky than CMYK on courser sub-straights such as fleece. It also has a lot of advantages when it comes to art that contains a lot of spot color.

Hopefully this has been an informative read that will help assist you when engaging in a print project. Feel free to reach out with any questions!

Leave A Comment