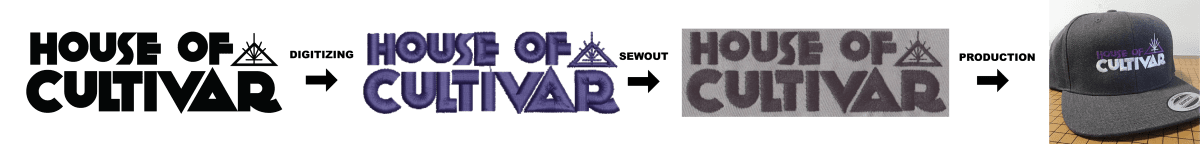

Welcome to embroidery basics where we’ll take a second to look at the sewout process from start to finish.

First thing to take into consideration is the resolution limitations of embroidery. The smallest stitch is about 2 – 3 millimeters across or roughly the thickness of a penny and the longest stitch is about 7 millimeters so thickness of a pencil.

Knowing that, imagine recreating your art out of building blocks that are no smaller than the 2 millimeters, that would represent the maximum resolution possible. Let’s also think about stitch count, the cost of embroidery is based on the amount of stitches used to replicate the design. As a guideline a solid square inch is roughly 2,000 stitches. Pricing can be found here.

All projects start with the art and garment. When initiating a project we take into account the following: Will the art fit onto the desired location on the garment? Does the changing size of the garment affect that condition? Will the machine and hoop fit on the garment in that location? Will sewing in that area potentially damage the garment?

Once we’ve covered the bases on sizing and location we’ll digitize the art for embroidery. Digitizing is the process of programming the art in a format that the embroidery machine can use to sew the design out. Think of it like a roadmap that the machine uses to find it’s way around the design.

Once the digitizing, measuring and compatibility checks are all wrapped up it’s time to start production. In order for the garments to be loaded onto the machine they must first be hooped. Hooping is the process of putting the garment into the frame that then mounts to the machine, the most common types of hoops are hat hoops and flat hoops. Hat hoops are circular to accommodate the the contour shape of headwear and flat hoops are used on 2D objects like jackets and tees. Shown below flats on the left and hats on the right.

Like screen printing quality embroidery is all about set up. Understanding the limitations and advantages then leveraging them to get a desired outcome.

Thanks for reading!

Leave A Comment