Custom Hats and Custom Beanies Seattle

When it comes to custom hats and custom beanies we have the right applications and experience to bring your logo headwear to life. For fast turnarounds, local craftsmanship and unmatched quality. The Foundry is your we’re your one stop shop. Patch and label making to direct embroidery and several types of printing applications all right here in Seattle. Back that up with our vast understanding of trends and qualities in headwear blanks. Serving the NorthWest with the best since 2010.

Custom Hats and Custom Beanies Seattle

When it comes to custom hats and custom beanies we have the right applications and experience to bring your logo headwear to life. For fast turnarounds, local craftsmanship and unmatched quality. The Foundry is your we’re your one stop shop. Patch and label making to direct embroidery and several types of printing applications all right here in Seattle. Back that up with our vast understanding of trends and qualities in headwear blanks. Serving the NorthWest with the best since 2010.

Custom Embroidered Hats and Beanies

Embroidery is a great and probably the most popular way to decorate headwear. For ball-caps we can embroider on the front, side and back for a custom look that works great for business, bands, schools or any organization looking to express their logo. Embroidery is also an effective way to embellish beanies, embroidery on beanies is an easy and effective way to create a custom value rich look.

Custom Sewn Patch Hats and Beanies

Patch application is an awesome method to customize headwear. Patches give a stand out look that is versatile and simplistic to apply. We have a post bed sewing machine that allows us to attach patches effectively to hats without crushing the crowns. Custom patch beanies are also a great usage for custom headwear applications, the patch form holds your art off the knit so your logo is legible and bold.

Custom Printed Hats

If it’s complex art that requires digitally printed or simple screen printed transfers we have the system that will match your custom headwear project. Heat applied printed transfers are cost effective and versatile making then one of the most popular custom headwear applications available.

Custom Woven Labels applied to Hats and Beanies

Woven labels are a clean and detail rich system for headwear decoration. Whether its a clip label with your logo for the back of your embroidered hat or its a woven label applied to the crown woven labels stand out as a premium and intentional look. Woven labels are also a great and possibly the most popular application for custom beanies. The more popular applications for custom beanies with woven labels are clip labels also known as book fold labels and flay end fold labels. Both give a simplistic and clean appeal to customized beanies.

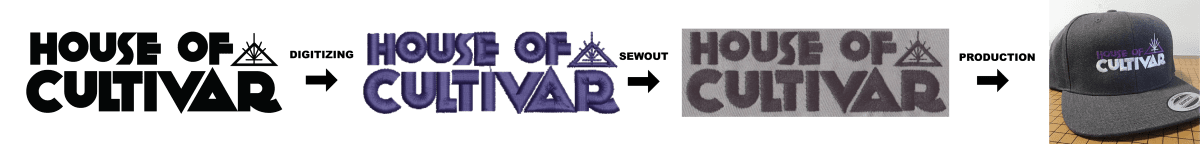

Welcome to embroidery basics where we’ll take a second to look at the sewout process from start to finish.

First thing to take into consideration is the resolution limitations of embroidery. The smallest stitch is about 2 – 3 millimeters across or roughly the thickness of a penny and the longest stitch is about 7 millimeters so thickness of a pencil.

Knowing that, imagine recreating your art out of building blocks that are no smaller than the 2 millimeters, that would represent the maximum resolution possible. Let’s also think about stitch count, the cost of embroidery is based on the amount of stitches used to replicate the design. As a guideline a solid square inch is roughly 2,000 stitches. Pricing can be found here.

All projects start with the art and garment. When initiating a project we take into account the following: Will the art fit onto the desired location on the garment? Does the changing size of the garment affect that condition? Will the machine and hoop fit on the garment in that location? Will sewing in that area potentially damage the garment?

Once we’ve covered the bases on sizing and location we’ll digitize the art for embroidery. Digitizing is the process of programming the art in a format that the embroidery machine can use to sew the design out. Think of it like a roadmap that the machine uses to find it’s way around the design.

Once the digitizing, measuring and compatibility checks are all wrapped up it’s time to start production. In order for the garments to be loaded onto the machine they must first be hooped. Hooping is the process of putting the garment into the frame that then mounts to the machine, the most common types of hoops are hat hoops and flat hoops. Hat hoops are circular to accommodate the the contour shape of headwear and flat hoops are used on 2D objects like jackets and tees. Shown below flats on the left and hats on the right.

Customizable Blank Hats

There and many ways to execute custom headwear projects. In most projects we customize styles from our blanks catalog, you can brows that selection at the button below. This is an easy and affordable way to create stunning custom headwear. There are many ways to decorate custom headwear from a blank, the most popular are embroidery, custom patches and custom woven labels. Mix and match these systems to get the perfect look for you custom hats and beanies.

Fully Customized Hats

As vast as our sourcing of blank hats is there are some projects that require a full custom approach. This means unique materials and a full form ground up design process. A full custom project comes with higher minimums and a longer lead time but the overall process is relatively simple. Reach out to us with your ideas and our team will work with you to make your fully customized hat dreams come true!

Custom Embroidered Hats

Custom Embroidered Beanies

Custom Patch Sewing

Custom Puff Embroidery

Custom Printed Hats